COBRA Applications

The following details are of COBRA systems that have be sold around the world:

Behr Maschinenbau GmbH in Blaichach, Germany

A regulated X-Z system from air-stored linear axles. Z-runner back at backs connected with the X-runner. Z stator, mass-reduced, implements vertical strokes with a load of approx. 5kg, taken up over suction grippers. The Z-axis is coupled to a force of gravity compensation and works on 0,1mm accuracy. Both axles are equipped with a totally enclosed encoder system.

Working envelope: X= 248mm; Z= 148mm.

RoBat in Bollington, England

2 Axes COBRA in 'X' and 'Y' direction which is moving a probe over a large printed circuit board used in telecommunications. The probe tests for bard circuits and bent electrical pins. The weight of the probe head is counterbalanced through gravity.

Working envelope: X = 1200mm; Y = 1400mm

Wella AG in Stuttgart, Germany

Air-stored X-Y-Z system fixed on granite stone, magnetic way measuring system, with a weight of 2.7kg on the Z-axis which is fitted with a gravity compensation device.

Working envelope: X = 600mm; Y = 300mm; Z = 500mm.

VD Optrionics in Eindhoven, Netherlands

Designed as a measuring system. The system is mounted on granite and runs without any 'cogging'. The purpose of the machine is to make very accurate measurements using various measuring instrumentation.

Prove Systems in Tayside, Scotland

A COBRA Planar drive used in the testing of DNA samples. The carriage has a rectangular hole into which a dish or tray of DNA samples is placed. The carriage moves each cell under a pipette which is then lowered into the sample for sampling.

Working envelope: X = 190mm; Y = 190mm

Betronic Hybrid Circuits B.V in Heerenberg, Netherlands

XY-Cross table for lasers from ceramics parts. Weight moved is approximately 3kg. Linear and circular movements and undertaken. The absolute positioning accuracy of 20µm is achieved. Due to difficult production conditions (shift operation and very hot ceramics) erosion of the stators is reduced by the use of bellows.

Name withheld

COBRA Planar system with both carriage and stator manufactured out of a highly alloye, high-grade steel with free movement in XY - direction. After reaching the desired position a brake is applied by switching off the air supply. This causes the carrage to come into contact with the stator resulting in a high holding force (brake). On this application pressing forces up to 20 tonnes are possible.

Corus in Hartlepool, England

A COBRA Planar drive with a rectangular hole placed in both the stator and carriage. A sample of steel bar is placed in the hole of the stator and a laser which is placed into the hole in the carriage fires the laser onto the surface of the bar. A spectrometer samples the material 'burnt off' and determines the content of carbon over the surface of the sample. The carriage uses Argon for the 'air bearing' instead of compressed air as this resultant argon atmosphere around the laser improves the quality of the results.

Hole dimensions

Carriage: 100mm x 100mm

Stator: 80mm x 80mm

Working envelope: X = 20mm; Y = 20mm

Sulfurcell Solartechnik GmbH in Berlin, Germany

Laser treatment of solar elements. The 'X' and 'Y' axes are embedded in granite for maximum system stiffness (vibration free) and highest accuracy attainment. The measuring system is centrally arranged and the 'Y' axis carries the laser system.

Working envelope: X = 2000mm; Y = 700mm.

Firma Intop in Frickingen, Germany

Optical laser examination of Silicon Waffers. Comprisiong a COBRA Planar system with a stator dimension of: 250mm x 360mm x 25mm. An encoder system is fitted into the XY slide guidance equipment.

BESSY GmbH in Berlin, Germany

A measuring device for the regulation of magnetic field integrals with magnet blocks. Comprises a COBRA X-Y system mounted on Granite block for a vibration free system with a maximum positional accuracy and repetition accuracy ≤1µm, angular movement of the carriage ≤ 5µrad.

Working envelope: X = 250mm; Y = 100mm.

Samsung in South Korea

A regulated COBRA X-Y system. The 'X' axis is laterally stored and has a very high clock rate and very high positioning accuracy. The system is used in the testing of printed circuit boards and controls the movement of a 3D head scanner.

Mühlbauer AG ASEM in Dresden, Germany

Three carriages are mounted on a single COBRA stator. Effectively this makes for a 3 axes system. Each carriage is controlled independently whilst being protected against collision. The system is located on a handling system.

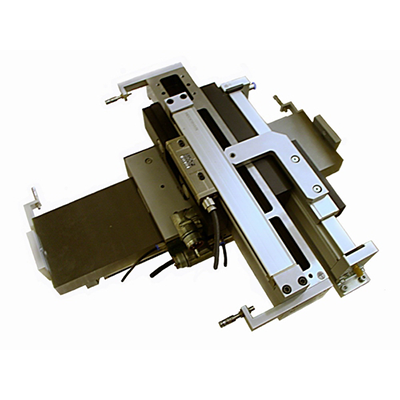

Robert Bosch GmbH in Immenstadt, Germany

A compact COBRA X-Y with a linkage system. Used formeasuring systems optically.

PASIM Direktantriebe GmbH in Suhl, Germany

X-Y-Z CNC milling machine for fabricating components. Comprising two 'X' axes and two 'Y' axes with the weight in the 'Z' axis being mechanically gravity-compensated. The axes are fixed on granite for vibration free running and maximum positional accuracy.

Request A Quote

If you have any questions please complete the form below and we will be intouch: